robot Aided Fabrication

Collaborators: Dyani Robarge, Rachel Sung, and Marnfah Kanjanavanit, Anthony Nitche. Supervised by Professor Jeremy Ficca

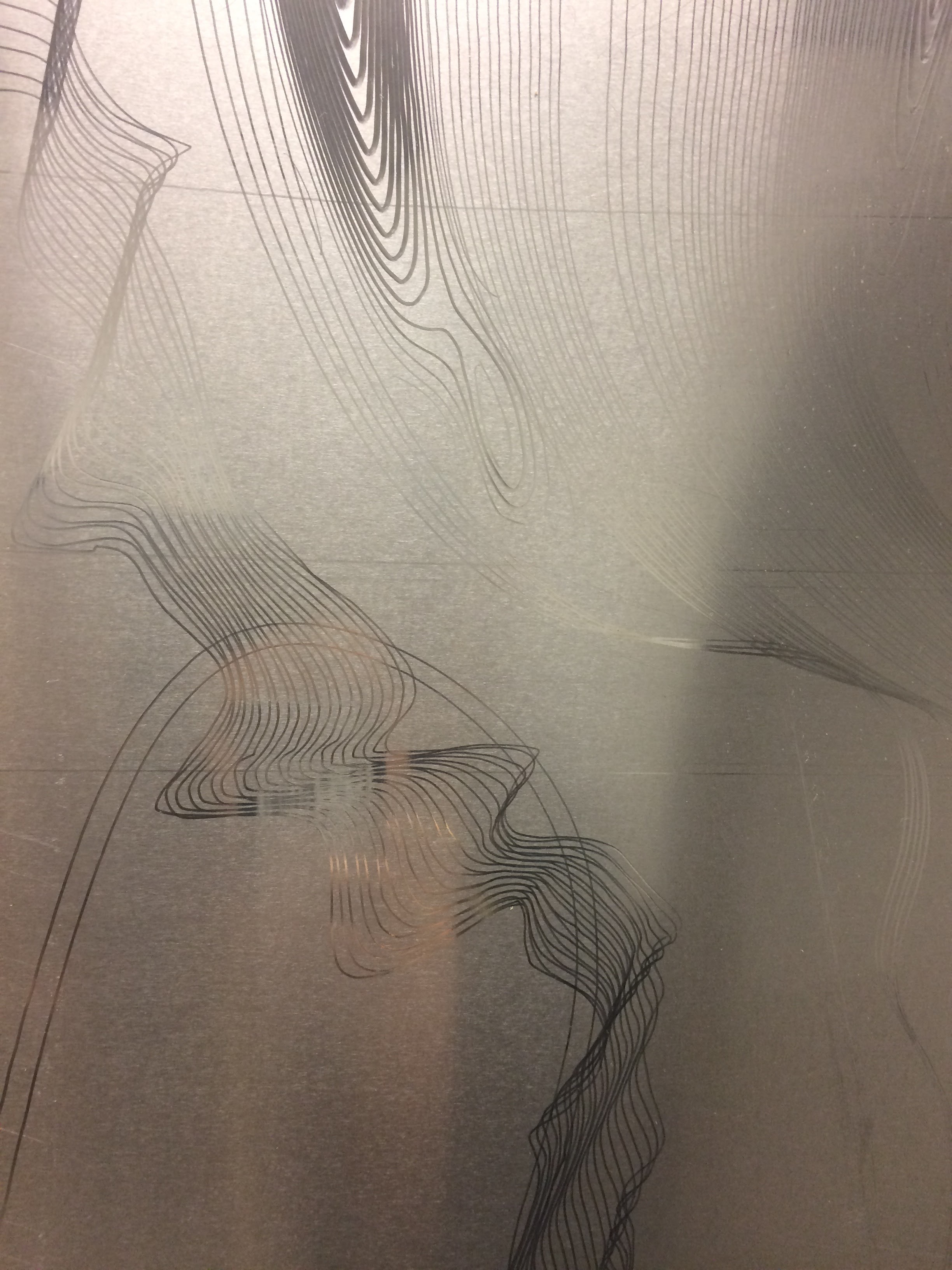

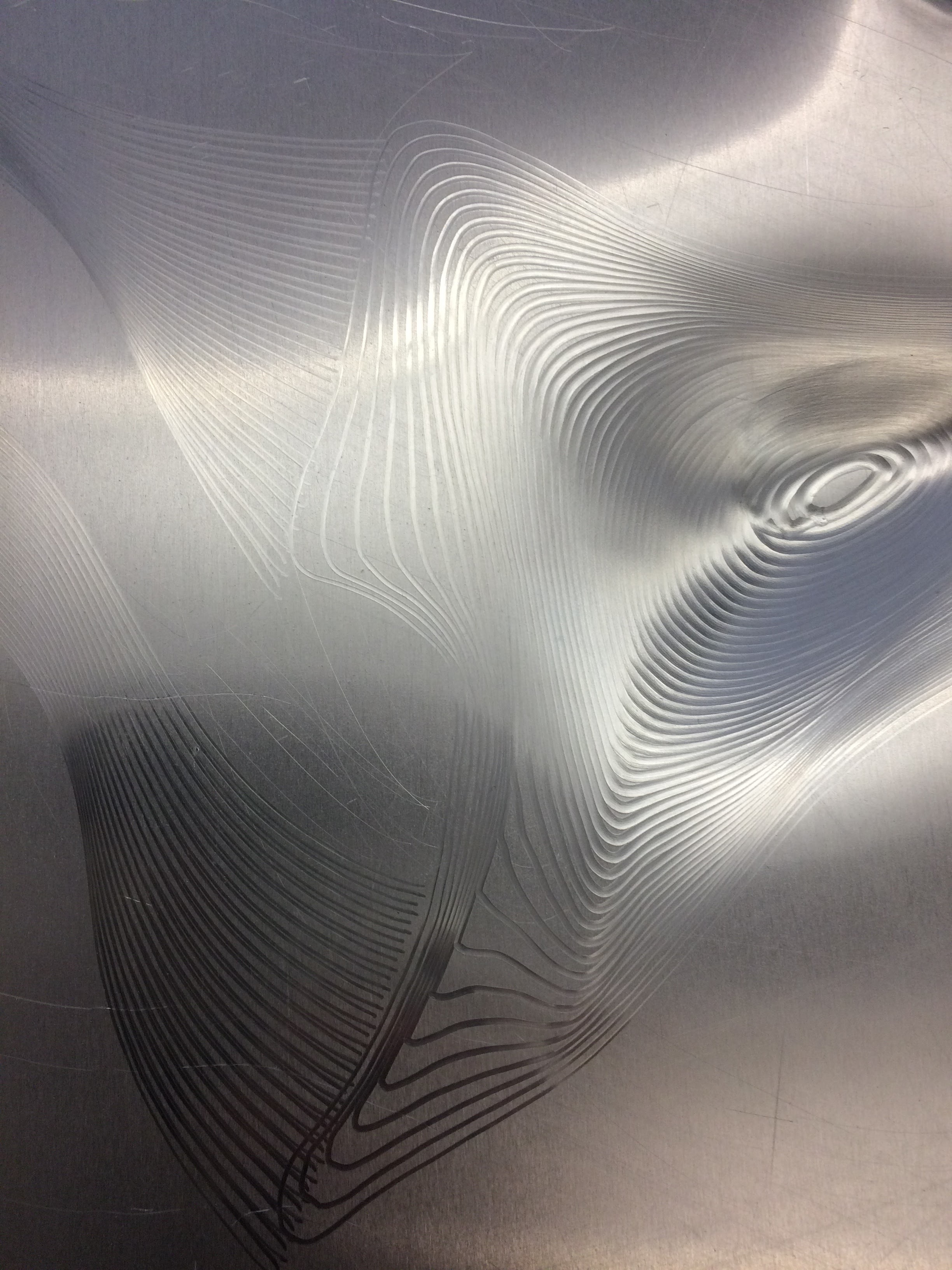

For a year, our team worked at the intersection of robotic fabrication and material studies to research the unique affordances of robots as partners (and tools) in the design of building cladding and sculptures. We conducted hundreds of rapid experiments with programmable ABB robotic arms and aluminum metal sheeting to develop strategies for organic-looking facade design. Using a proprietary Grasshopper + Rhino package, the team developed material and software combinatory approaches to solving many of the challenges that arise from shaping metal through robotic force (e.g., warping, tearing, misalignment).

Theory met practice during the design, (robot-aided) construction, and installation of TactAl in the main foyer of Carnegie Mellon University’s Fine Arts building in spring 2017. Our work was supported by CENTRIA, who supported used the findings and insights to inform architectural cladding system strategies.

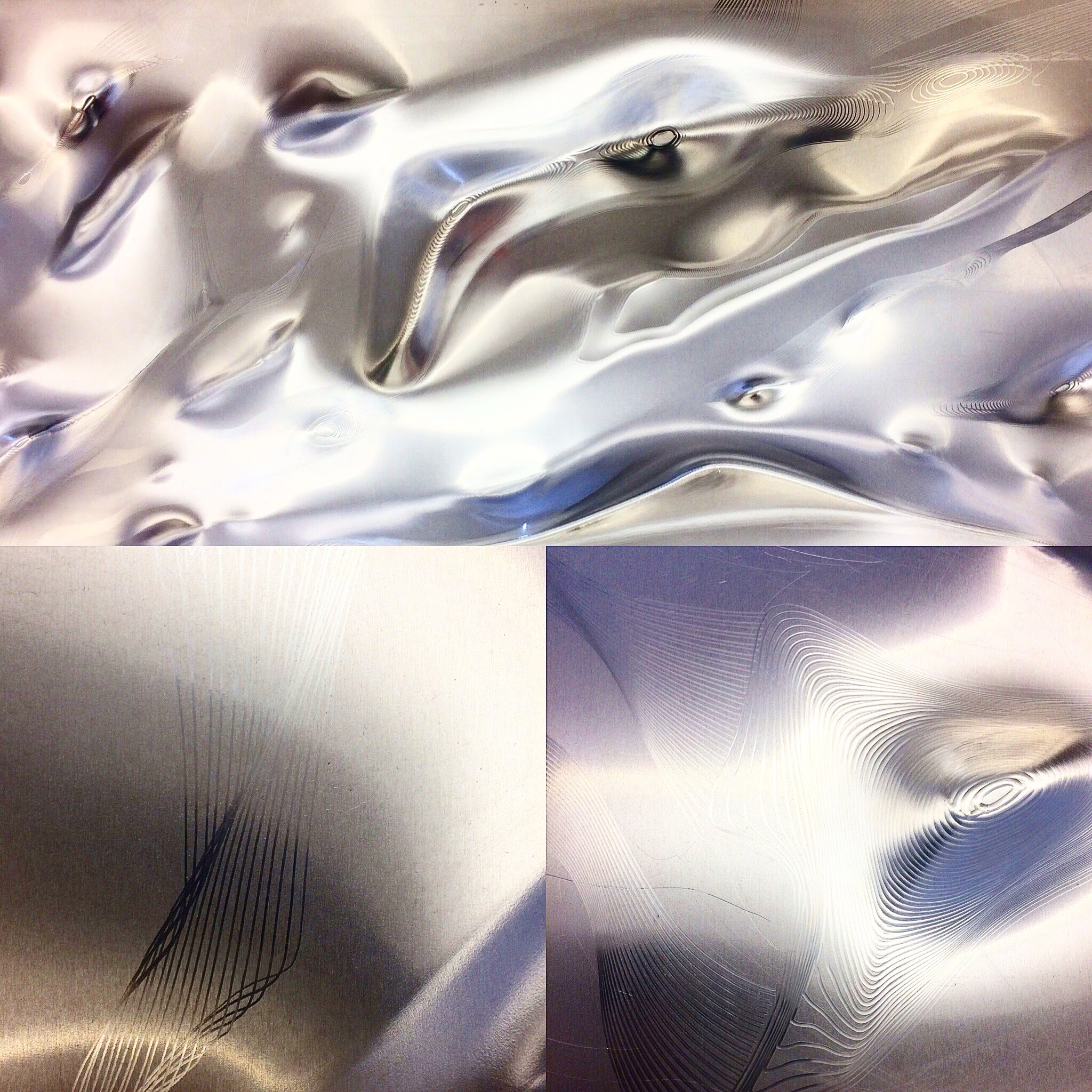

TactAl, rendering by Anthony Nitche

Installation // Photograph by Anthony Nitche

Fabrication + Robotic Research

As an emerging discipline, we had to dedicate months of work to better understand the relationship between the affordances of the metal and the software used to control the robot’s movements in applying pressure with tools we designed for the specific task of shaping aluminum cladding into organic structures.